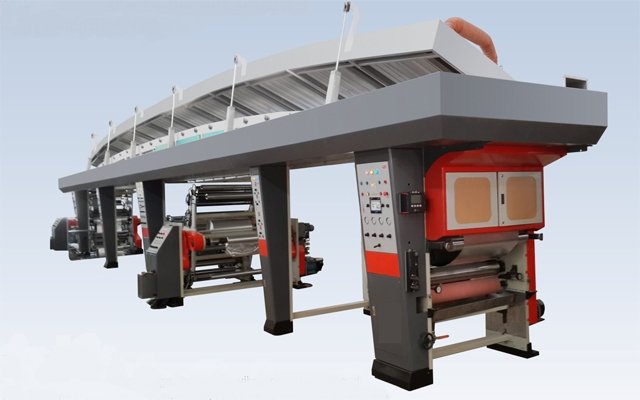

VMCH Coating Machine

ACCUWEB has developed special type VMCH Coating Machine

Technical Specification Of V.M.C.H Coating

- Working Width : 1250 mm

- V.M.C.H coating on Aluminum foil, and to Apply a thin coating of shellac on reverse foil surface in a single operation.

- Dry lamination of two webs

- Speed : Solvent base adhesive speed 100 mtr/minute

- VMCH Coating for foil speed 4 Gsm 40 to 80 mtr/minute and 6 Gsm 40 to 50 mtr/minute

- Water base adhesive coating speed 35 mtr/minute

- 1) Shellac coating : Gravure method Separate three air blower for shellac wash unit Air nozzles distribute uniform not air across the wash width and are placed against idle rollers for proper web support Air volumes can be controlled by manual dampers at each station

2) V.M.C.H coating : Three roll coating system / Gravure method - Pneumatic application for pressure roller, Doctor blade, Drying hood and Nip unit. Screw type adjustable roller at different points

1st Gravure Printing Station � 1no.

- Station Plate ; 1800 mm X 500 mm X 40 mm (Solid Plate)

- With "SHANTHI" Make main gear box

- Rubber roll pneumatically operated (Compressor not in our scope of supply)

- Doctor blade manually operated

- With sufficient no. of Aluminium rolls of 3 " & 4 " Dia

- Maximum Cylinder circum : 1000 mm

2nd Coating Head Tree Roll System : Same As Above But

Rewinding Station :/Unwind Station

- AIR SHAFT type rewinding station with motor(load cell base drive contol)

- 2NO Unwinding Station : complete with 1 No. Web alinger ( Accuweb Make) with station plates with 6 caliper Pneumatic Brake ( Load cell based )

- Maximum Unwinding Roll Dia: 1000mm

Tunnel

- Total Tunnel length : 36 Ft ( 6 Ft X 6 ) High velocity VMCH drying system equipped with insulated drying tunnel

- Shellac drying system equipped with insulated drying tunnel of total 18FT(6ftx3) length

- For hot air required in the tunnel , 2 Lac Kcal OR 2.5 Lac Kcal hot air generated ( diesel fired ) along with the necessary ducting ( Insulated) shall be in buyer scope of supply.

- Inlet hot air shall be supplied from top of the tunnel .

- top door opening shall be provided for the tunnel

- A cat walk, along with ladder shall be provided by us on n one side of tunnel

- Top (VMCH) dryer rollers are of teflon coated to protect laquire shifting from coated foil

- For stable working of the machine , Sufficient no. of Vertical & Horizontal supports of channels & angles shall be provided

Electricals

-

Electrical Motors

- 3 H.P. A.C. � 3Nos. ( 1 No. each For 1st gravure , 2nd three rol coating,+36 ft tunnel , )

- 7.5 H.P. A.C.- 1No. ( For Rewinder )

- .5 H.P. A.C.- 1No. ( For laminating )

- 6 caliper Pneumatic brake with Load cell based for 2nos unwind

- motors of Coating Machine shall be of "BHARAT BIJLEE" OR "ABB". Balanced other motors like Blowers motor p.pack shall be of Standard make (as per mfg supply)

Drive System

- Drive system synchronized for coating+laminating+rewind+tunnaldrive ( also Motor & Brake ) Touch screen type base

- Panel shall be supplied along with the necessary control cables required for the same . Out of the above motors � 3 H.P. A.C. � 3Nos. motors shall be with load cell & 1 No. � 5 H.P. motor for rewinder & Unwinder Pneumatic Brake of 6 caliper Capacity shall be with load cell .

- 2 Nos. 3 H.P. conveyor motors shall be without load cell .

- All internal electrical power connection including required necessary cables not in our scope of supply . You shall provide us the connection upto our drive and all panel wiring

- All above electrical motors shall be "ABB" OR "BHARAT BIJLEE" Make

Salient Features of the Plant

- This machine is specially designed as a multipurpose plant, With additional facilities like polyester lamination silicon coating, adhesive coating for tapes and stickers, heat sealable coating on blister etc.

.jpg)

|

.jpg)

|